03/11/2019

Dies for cable stranding and compacting

Stranded cable producers have more options today than ever before in choosing the optimum bunching, stranding or compacting die for their unique application. “Nano Diamond Coated Dies” are the newest addition to the family. Understanding the tradeoffs is important in making the right decision.

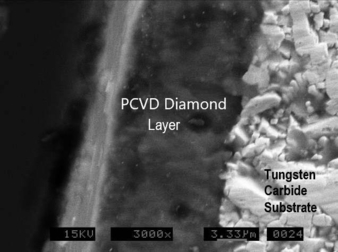

Prior to the advances in PCVD diamond coating technology that solved the adhesion problem and allowed a thick film diamond coating to be economically applied to a tungsten carbide substrate, the only wear resistant die option for stranding or compacting large diameter cables (> .95” or 33mm) was tungsten carbide. However, the demand for longer continuous length subsea power cables and the need to lower production costs on a host of other stranded cable products has created a need for a longer lasting die material for large and small diameters.

Fort Wayne Wire Die (FWWD) has introduced the “Nano Diamond Coated Dies” (NDCD) for stranding, bunching and compacting applications in the cable industry. This product line complements and extends the solutions-based product offering the company has to offer the cable industry. The introduction of Nano DCD dies now provides the widest range (see fig. 1) of hole diameters available in the industry – from .030 – 4 inches (0.8 – 100mm).

NDCD dies are tungsten carbide dies that have been coated with a 30 micron thick layer of nanocrystalline diamond particles (see fig. 2). The entire interior surface of the die is coated, including the entry area which is an especially important part of the die for stranding dies. The diamond particles in the coating are very small- only 50 nanometers in size. After being polished, the die surface becomes extremely smooth compared to tungsten carbide or PCD (see fig. 3a-c). This low friction, high luster surface finish minimizes die pull for improved energy efficiency of the stranding machine, reduces fines and dust generation, and creates a smoother cable surface finish. Fines and dust are an especially serious problem when drawing aluminum cables. Aluminum fines are an explosion hazard, so minimizing them is an important safety concern.

Of course longer die life is one of the biggest advantages of NDCD dies. Compared to tungsten carbide, die life is about 10x (or more) while die cost is only 3-5x more, so there is often a strong value proposition in using NDCD dies over tungsten carbide dies apart from the quality, safety and energy efficiency benefits already mentioned.

Minimizing die wear can have a huge impact on the cost of production in ways not always obvious. Typically power cables are sold by length, not by weight, and the cable conductor’s raw material is often the biggest fraction of a finished power cable’s cost. When designing a cable, the circular mil area and overall diameter is determined that will meet or exceed the minimum conductivity requirements of the cable producer’s customer. However, during production, dies wear, and as they wear the compacted cable becomes larger. That “extra” raw material that is being given away for free with every micron of wear has a surprisingly large cost associated with it.

For example, take a 1.20 inch (30.5mm) tungsten carbide die that has drawn 60 miles of copper cable and over the time of use wore .005” oversize to 1.205 inches (30.6mm). Let’s assume for the sake of discussion that the wear was linear over the life of the die. If you perform the calculations, that .005” excess copper over 60 miles at $2.78/lb. comes to $15,959 of “free” copper that was given away. Reducing die wear has a positive effect on a die budget but as this example illustrates, there is a much bigger potential savings coming from a reduction in raw material cost.

Although FWWD Nano DCD are available in sizes as small as .031 inches (0.8mm), where they really shine is in the larger sizes. Currently die manufacturers are limited to a maximum hole size of 1.3 inches (33mm) with Polycrystalline Diamond (PCD). PCD dies in the largest sizes become exorbitantly expensive. Therefore, generally speaking, the smaller the hole size the stronger the case for PCD and the larger the hole size the stronger the case for NDCD.

Nano DCD dies are throw away dies. They cannot be re-polished, recut or re-coated. The “throw away” characteristic can be viewed in positive or negative light. The purchase price of a new Nano DCD die is usually less expensive than a new PCD die, but it is not that simple. If properly cared for, PCD dies can be re-polished and reused multiple times without changing the hole size. The cost of re-polishing a worn PCD is usually less than the cost of a new Nano DCD die. So the question of cost effectiveness really depends on how much tonnage is needed to be run of a particular size. Is the application a standard size that is run year around, or a small volume, one off order? A total cost of ownership approach should be taken in making these determinations.

Nano DCD dies join other products already in the Fort Wayne Wire Die line up for stranding, bunching, compacting and compression applications, and each product has it’s own distinct advantages and disadvantages from a cost and performance standpoint. There are many criteria to consider when choosing the best solution for a given application (see the Stranding Die Selection Table in fig.4).

Tungsten carbide (WC) dies are the lowest cost option in a wear resistant material. They are good for short runs, test runs, and are widely available in small and large sizes (available from FWWD up to 2 inches, 50mm). They also have the advantage of being recuttable. The drawback to WC dies is their limited die life and propensity to gradually wear oversize while in use, making them a poor choice for long production runs, or where superior surface finish and maintaining a stable hole size is critical.

Tungsten carbide split stranding dies are comprised of two die halves that are bolted together during use. They are popular for their ease in stringing up and because of the convenience of being able to change dies without cutting the wire. Wire surface finish is sacrificed a little bit with split dies due to the “seam” that is created where the two die parts come together. Nano DCD is not recommended for split stranding dies because of adhesion problems at the seams, however, PCD split stranding dies are beginning to make their way into some applications.

Solid Polycrystalline Diamond (PCD) stranding dies have the highest up front cost but from a total cost of ownership perspective may be the most cost effective on high volume production runs and smaller diameters. PCD dies are limited in hole size to about 1.3 inches (33mm)* but are harder to cost justify against NDCD dies in hole sizes over .95 inches (24 mm). They have the advantage of being able to be re-polished multiple times without changing the hole size, and are capable of holding smaller tolerances for longer periods of time than the other die options.

The die life of PCD dies vs. Nano DCD dies depends a great deal on the reason for die failure, or the change in a characteristic that leads to a dies removal from the stranding machine. If the reason for die change is related to wire surface finish, there may be very little difference in die life between a NDCD die and a PCD die. If die failure is determined mostly by a change in cable diameter, PCD dies usually have the performance edge.

Die Wear

Many of us in the wire industry are familiar with the way traditional die materials such as tungsten carbide and PCD wear. Dies made from these materials typically develop a wear ring in the reduction angle just below the point of impact of the wire or stranded cable. This wear develops due to a combination of friction and heat (abrasive wear), and gradually grows deeper until the bearing area, which controls the cable diameter, becomes compromised.

Both PCD and WC are aggregate materials that are composed of a combination of “hard” particles (diamond or tungsten carbide) and a softer material such as cobalt that acts as a binder in tungsten carbide and a catalyst in PCD. Wear rings develop in a similar fashion in both materials – a hard particle is pulled out leaving a small void in the die surface. During use, this happens at the wire impact point a multitude of times at a micro level leaving a ring-like wear pattern on the die.

Despite their similarities, PCD die wear is different from WC die wear in one important aspect. Although PCD dies will develop a wear ring, the bearing of a PCD die sees little to no wear for a very long time - even after many years of use. Over time the wear ring in a PCD die will eventually grow deep and pronounced enough that “wire marks” will begin showing up on the cable surface. This is typically when a PCD die is removed from use. Most of the time, a PCD die that has been removed for this reason can be repolished and returned to use without enlarging the hole size. This convenience is made possible due to a lack of wear in the bearing of PCD dies.

Nano DCD dies wear in a much different manner. Because of their small size and the way the nanocrystalline diamond particles have been grown, the surface of the NDCD die after polishing is very smooth and slick, approaching the surface finish of polished single crystal diamond. Nano DCD dies do not develop a distinct wear ring the way PCD and WC dies do during use. There is very little noticeable wear in NDCD dies prior to failure (see fig.5). When failure occurs it is caused by a sudden delamination of the diamond coated surface. Once this happens a change in cable surface finish is often noticeable making the dies unusable. NDCD’s are exceptionally resistant to wear – there is almost no change in hole size or surface degradation prior to failure. Die life is at least 10X over tungsten carbide, and they are frequently known to produce as much as 600 miles (1,000km) of cable before failure.

In conclusion, there is no one die that is optimum for all stranding and compacting applications. Many factors should be considered in making the selection from a performance, quality and total cost of ownership perspective. Nano DCD Stranding and Compacting dies, however, are a proven and legitimate option that all cable producers should consider, especially for large diameter, high production volume applications. Fortek GmbH is a 100% daughter company of Fort Wayne Wire Die Inc. and is responsible for the sales and support of the European Market.

* The hole size availability of Solid PCD dies from Fort Wayne Wire Die is extended to 1.3 inches (33mm) by the use of the proprietary “Poly-Strand” design which combines a replaceable tungsten carbide cap in the die entry with solid PCD in the reduction and bearing zones.

Brad Scherer, Fort Wayne Wire Die, Inc.

Fort Wayne Wire Die, Inc.

2424 American Way

Fort Wayne, IN 46809/USA

Contact person is Brad Scherer

Tel.: +1 260 7471681

Fortek GmbH

Beyerbachstrasse 1

65830 Kriftel/Germany

Contact person is Hartmut Buchfink

Tel.: +49 6192 25028