07/10/2019

New bending process for “Hairpin” production

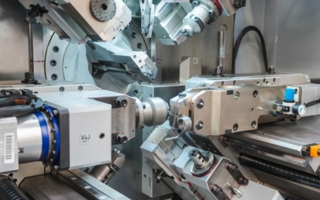

Hairpins are challenging bent wire components made of copper wire as the core element, clad in a layer of insulation. These electrically conductive parts are used in the new generation of hairpin motors.

These components are subject to very demanding requirements in terms of their geometry and surface properties. Existing manufacturing processes such as those involving the use of automatic multi-slide units or transfer systems usually entail a high level of overhead in terms of tool set-up and programming work, as well as substantial tool costs.

With the wealth of experience that comes from 125 years spent forming wires and tube components of all kinds, Wafios elected to shoulder the challenge of hairpin production. The result? Quite simply the most flexible machine currently available on the market.

This flexible new process means that the majority of hairpin geometries for a stator, including the connection assemblies required, can be manufactured in any sequence without the need to change tools.

A patent for this bending process has been applied for, a process that enables bending work to be accurate and free of physical damage. This is a field in which Wafios has many years of experience. The measurement and feedback control algorithms this process employs ensure that the machine is able to monitor and control itself during production operations. Even in situations where the paint gets stripped inadvertently from the contact points, Wafios is a competent partner, one able to offer various solutions to suit customer wishes.

Geometric programming dispenses with the need for the user to program individual CNC axes. This speeds up the definition of hairpin geometry.

Flexibility depends on the geometric programming of bending parts and/or hairpins. The Wafios controller “WPS 3.2 Easy Way” also allows you to import 3D geometries automatically with Step/Iges files. After the co-ordinates have been imported, the requisite bending program can be produced automatically.

There is also the option of integrating and using the simulation tool to run through the complete production sequence of the bending component. The entire process is simulated using a digital twin, including machines, tools and workpieces to create a dependable collision check in advance. The entire production planning process, including the programming of parts, simulation, definition of cycle time and the collision check, can be performed in a parallel manner at an external programming station. In addition, simulation is used to establish the optimum tool arrangement for the specific bending part.

Wafios AG

Silberburgstrasse 5

72764 Reutlingen/Germany

Tel.: +49 7121 146-0